Multi-purpose linear vibrating screen

这里是标题一h1占位文字

VRV vibrating screen is applied in material screening, ore washing, grading, desliming, media removal, dehydration, recovery, and impurity removal. VRV equipment can adapt to various harsh working conditions that easily cause corrosion and wear.

Keyword:

Conveying activation | screening | vibrator/controller

Category:

Product Description

VRV linear vibrating screen Customized for screening multiple materials

VRV vibrating screen is applied in material screening, ore washing, grading, desliming, media removal, dehydration, recovery, and impurity removal. VRV equipment can adapt to various harsh working conditions that easily cause corrosion and wear.

Advantages

● Single or multi-layer screen

● Rational vibration parameters to avoid the natural frequency and resonance effect of the system

● According to application requirements, the side plates and reinforcing ribs can flexibly adopt Hooke riveting or welding so as to ensure that the side plates are free of stress concentration and cracking, and the strength and rigidity of the side plates are improved, thereby boosting equipment reliability.

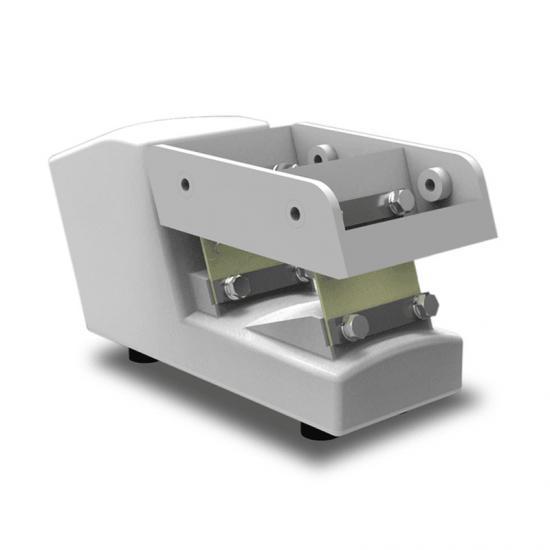

● The vibration exciter beam and screen frame beam adopt a box beam structure with reinforcing ribs inside to improve the rigidity and strength of the screen machine, and reduce the overall weight at the same time, thereby improving the overall efficiency and reducing power consumption.

● After welding, the vibration exciter beam and all beams are annealed to relieve stress and machined along with the installation section of the side plate.

● The life of the vibrating screen body is as long as 10 years

Key Data

● Width 4500mm

● Length 11000mm

● Work volume 3000T/H

● Long service life; the service life of the screen body is as long as 10 years, and the driver can last over 60,000 hours

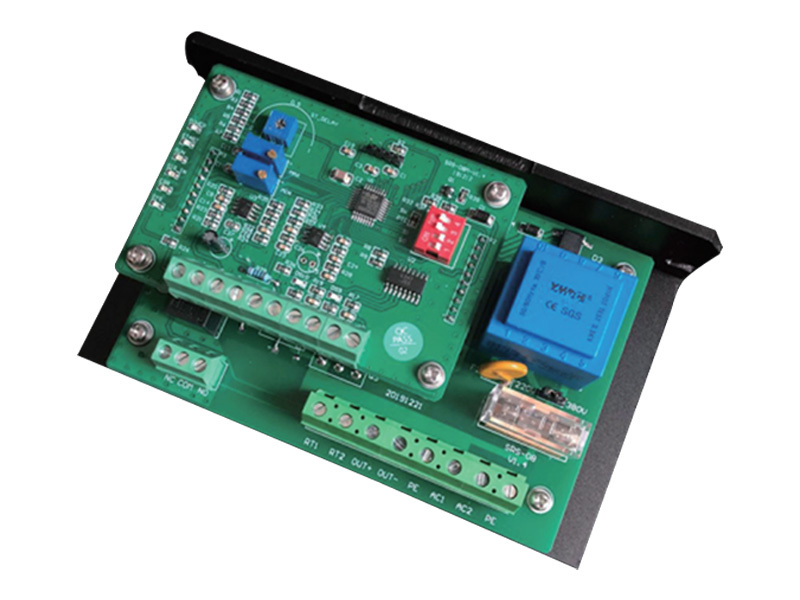

● Two driving methods are optional, namely, vibration motor and vibration exciter

Related Products

Welcome to your message consultation