EV series electromagnetic driver

这里是标题一h1占位文字

EV series electromagnetic vibrators are suitable for various forms of vibration equipment solutions. Due to the inherent characteristics of the electromagnetic vibrator, the vibration drive system is the first choice when all kinds of bulk materials need to be metered and conveyed quantitatively. Its non-lagging start and stop is a good choice for the process with strict requirements for crossing the resonance zone.

Keyword:

Conveying activation | screening | vibrator/controller

Category:

Product Description

EV series electromagnetic vibrators are suitable for various forms of vibration equipment solutions. Due to the inherent characteristics of the electromagnetic vibrator, the vibration drive system is the first choice when all kinds of bulk materials need to be metered and conveyed quantitatively. Its non-lagging start and stop is a good choice for the process with strict requirements for crossing the resonance zone.

Working Principle

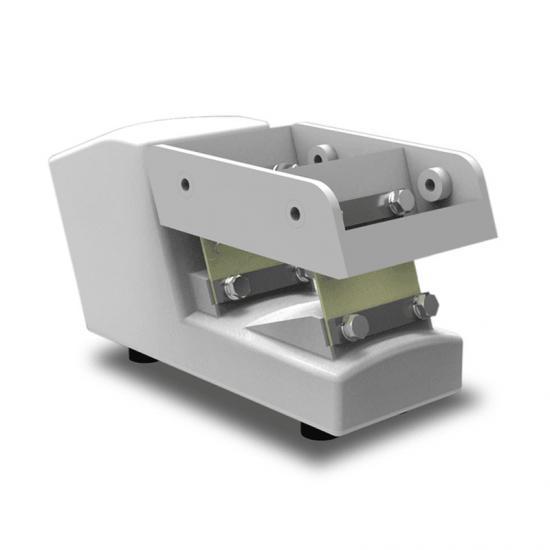

The electromagnetic vibrator is a system combining a mass body and a spring, and the vibration force generated by the vibrator is directly transmitted to the tank body without additional equipment such as a belt transmission shaft, a frame and the like.

The electromagnetic vibrator generates a linear vibration displacement, and the displacement direction keeps a fixed angle with the horizontal direction. The effective vibration stroke has a double relationship with the amplitude of the whole vibration equipment, which determines the height of the material bouncing, thus affecting the conveying speed of the material. The actual conveying capacity depends largely on the cross-sectional area of the conveying trough and the bulk density of the bulk material.

The direction of vibration delivery is determined by the vibration angle and the resultant force.

The electromagnetic vibrator can realize stepless adjustment by adjusting the access voltage. After starting, it can reach the full-load operation state instantaneously, and there will be no start-stop delay like the vibration motor. Because of this characteristic, electromagnetic vibrators are particularly suitable for highly demanding processes such as dosing. Bidirectional conveying and feeding need to realize the alternate conveying of materials in two directions, which can be realized only by changing the phase of the power supply of the vibrator.

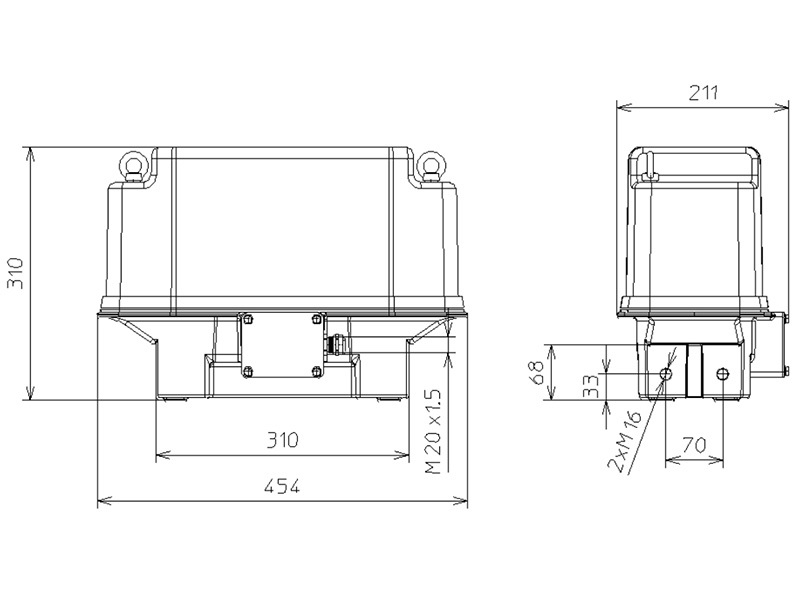

EV100

| Model | Operating Frequency | Current/A | Maximum Operating Weight/Amplitude | Weight | ||

| 230A | 400A | Max.kg/mm | Min.kg/mm | |||

| EV100-25 | 25 | 10.5 | 5.8 | 130/1.0 | 33/3.0 | 45 |

| EV100-33 | 33 | 9.5 | 4.9 | 70/2.0 | 40/2.8 | 48 |

| EV80-50 | 50 | 5 | 3.5 | 85/0.5 | 35/1.6 | 55 |

| EV100-50 | 50 | 6 | 3.8 | 150/0.6 | 40/1.6 | 60 |

| EV120-50 | 50 | 7 | 4 | 165/0.6 | 50/1.5 | 65 |

EV150-EV200

| Model | Operating Frequency | Current/A | Maximum Operating Weight/Amplitude | Weight | ||

| 230A | 400A | Max.kg/mm | Min.kg/mm | |||

| EV150-25 | 25 | 14 | 9 | 230/1.4 | 110/3 | 116 |

| EV150-33 | 33 | 14 | 10 | 250/1.2 | 80/2.8 | 116 |

| EV150-50 | 50 | 13 | 8 | 320/0.5 | 110/1.6 | 120 |

| EV200-33 | 33 | 15.5 | 11 | 300/1.2 | 100/2.8 | 116 |

| EV200-50 | 50 | 14 | 10 | 360/0.7 | 110/1.8 | 120 |

| EV250-33 | 33 | 16 | 11.5 | 330/1.3 | 110/3.3 | 120 |

| EV250-50 | 50 | 15 | 11 | 360/0.8 | 150/1.8 | 130 |

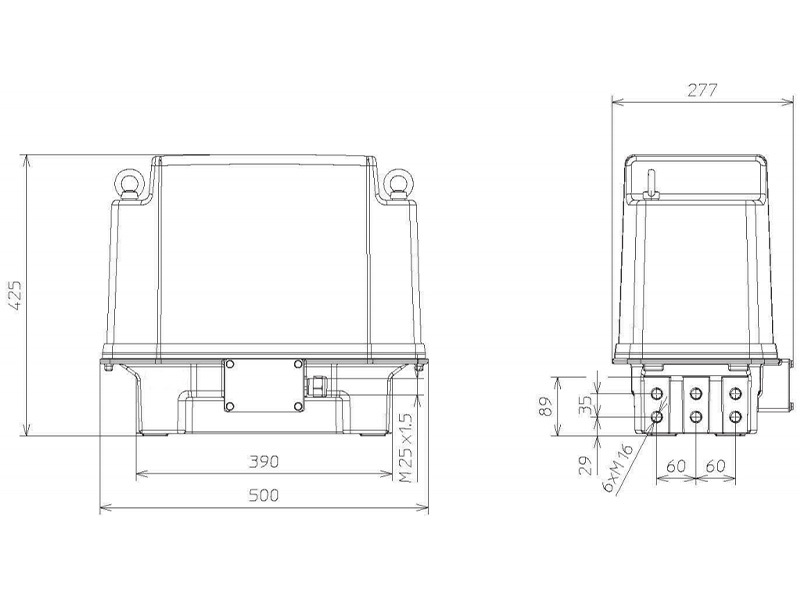

EV300

| Model | Operating Frequency | Current/A | Maximum Operating Weight/Amplitude | Weight | ||

| 230A/50Hz | 400A/50Hz | Max.kg/mm | Min.kg/mm | |||

| EV300-25 | 25 | 20 | 18.5 | 450/1.5 | 220/3 | 260 |

| EV300-33 | 33 | 14.5 | 600/1 | 200/2.5 | 260 | |

| EV300-50 | 50 | 14 | 600/0.7 | 210/1.9 | 265 | |

| EV350-33 | 33 | 14.5 | 650/1.1 | 220/3.2 | 265 | |

| EV350-50 | 50 | 16 | 650/0.8 | 210/2.2 | 280 | |

| EV500-33 | 33 | 25 | 900/1.5 | 300/3.8 | 350 | |

| EV500-50 | 50 | 22 | 700/0.8 | 300/2.3 | 350 | |

| EV1000-33 | 33 | 45 | 1650/1.5 | 700/3.8 | 700 | |

| EV1000-50 | 50 | 42 | 1200/1.0 | 550/1.8 | 750 | |

Related Products

Welcome to your message consultation